Home Heating Systems: Types, Efficiency, and Cost Considerations

Types of Home Heating Systems and How They Work

Before diving into details, here is a brief outline of what follows so you can navigate with purpose:

– A tour of major system types and how heat moves through a home

– Efficiency metrics and what they mean in real climates

– Cost breakdowns: upfront, operating, maintenance, and lifespan

– Sizing, distribution, and the home envelope’s role

– Controls, upgrades, incentives, and a step-by-step decision guide

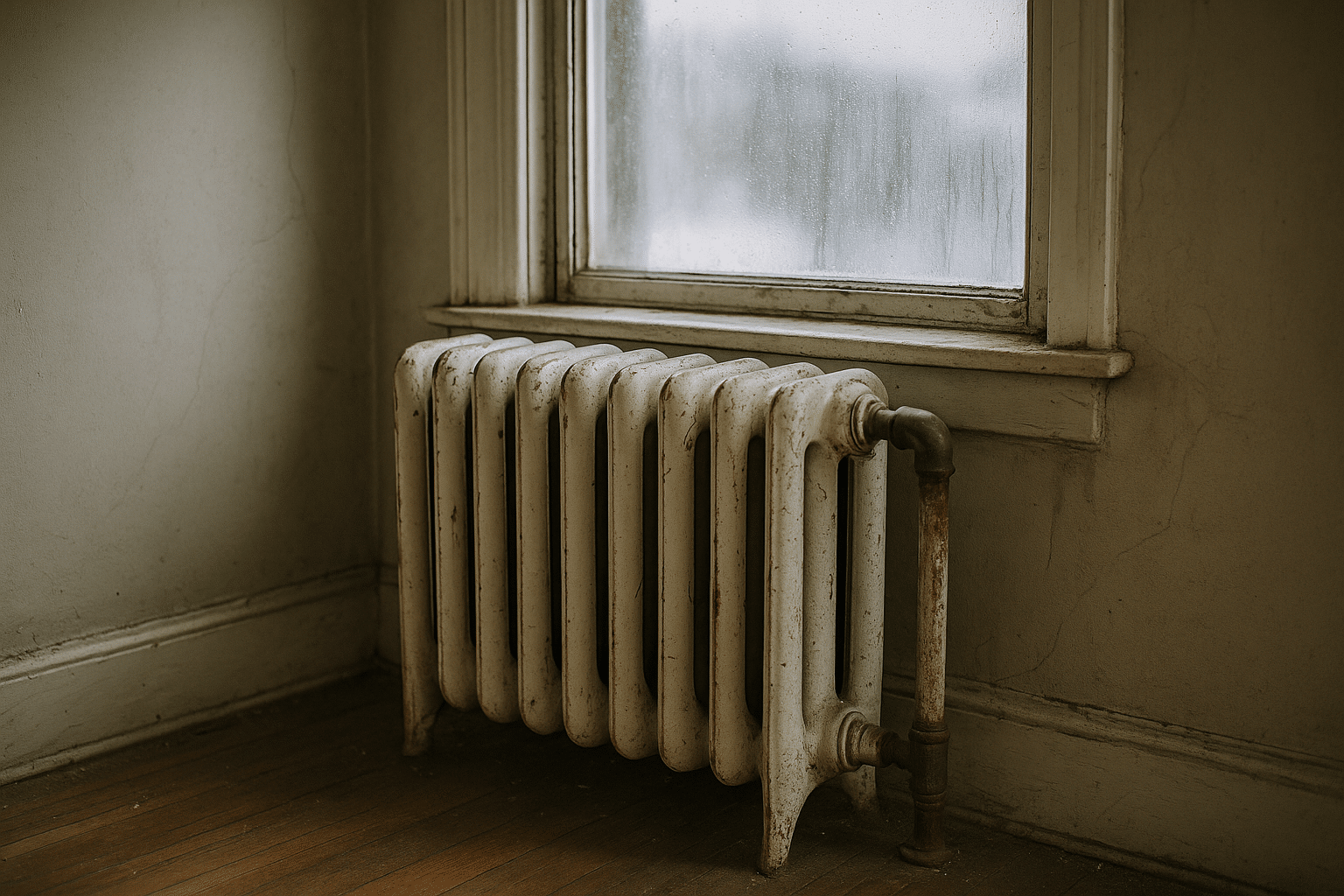

Home heating systems fall into a few broad families, each defined by the heat source and the way warmth is delivered into rooms. Forced-air furnaces burn a fuel or use electric resistance to heat air, then push it through ducts to registers. Hydronic boilers heat water and send it through radiators, baseboards, or radiant floors, releasing heat as the water circulates. Heat pumps move heat rather than create it: air-source models pull heat from outdoor air, while ground-source systems draw it from stable soil or groundwater temperatures via buried loops. There are also space heaters—pellet, wood, or electric—used as primary sources in small homes or as supplemental heat in larger ones.

Understanding these differences helps you match a system to your building and climate. Forced-air systems pair easily with filtration and humidity control, and they can share ductwork with cooling. Boilers excel at steady, even heat and quiet operation, with radiant floors offering a comfortable low-temperature approach that pairs well with high-efficiency boilers or heat pumps. Air-source heat pumps have advanced significantly, with cold-climate models maintaining output at lower outdoor temperatures, and ductless variants providing targeted “zoned” heating in homes without ducts. Ground-source heat pumps deliver high seasonal efficiency and stable performance but require space for loops and a higher initial investment.

Choosing delivery methods matters as much as the heat source. Ducts must be properly sealed and insulated to avoid losses, especially in attics or crawlspaces. Hydronic systems depend on well-sized emitters and balanced circuits to keep temperatures even between rooms. Radiant floors typically run at lower water temperatures, enabling higher efficiency and gentle comfort. Space heaters can solve localized cold spots, but whole-house solutions usually provide better efficiency, controllability, and safety. Put simply, think of your house as an ecosystem: the heat source is the heart, but distribution is the circulatory system that determines how well warmth reaches every corner.

Efficiency Metrics, Comfort, and Real-World Performance

Efficiency labels translate engineering into something you can compare across systems—provided you know what the acronyms mean. AFUE (Annual Fuel Utilization Efficiency) rates furnaces and boilers on how effectively they turn fuel into heat over a season. Typical modern gas furnaces and many boilers reach AFUE values around 90–98%, while older units can drop below 80%. Electric resistance heat is effectively 100% at the point of use, but that does not make it economical; electricity usually costs more per unit of heat delivered unless a heat pump is used. Heat pumps have two main measures: HSPF or HSPF2 for heating season performance, and COP (Coefficient of Performance), which expresses how many units of heat are delivered per unit of electricity consumed. A COP of 3 means three units of heat for every unit of electricity.

Numbers on a label are helpful, yet climate and installation quality can change outcomes. Air-source heat pumps lose capacity and efficiency as outdoor temperatures drop, requiring careful sizing and, in colder regions, a plan for supplemental heat. Modern “cold-climate” models maintain useful output well below freezing and can deliver a seasonal COP between roughly 2 and 4, depending on climate and home load. Boilers paired with oversized radiators or radiant floors can operate at lower water temperatures, improving seasonal efficiency versus high-temperature operation. Duct systems that are leaky or uninsulated can waste a significant fraction of heat before it reaches living spaces, so sealing and insulating ducts can raise real-world efficiency by double-digit percentages.

Comfort is the other half of the equation. Even distribution, stable supply temperatures, and responsive controls often matter more day-to-day than small efficiency differences. Boilers and radiant floors excel at quiet, steady warmth that reduces temperature swings. Forced air can deliver quick temperature changes and can handle filtration, which helps with indoor air quality. Heat pumps shine in shoulder seasons, modulating up and down to match mild loads with very high efficiency.

Environmental impact varies by fuel and by the local electricity mix. As a ballpark, combustion emissions are roughly: natural gas about 53 kilograms of CO2 per MMBtu, propane around 63, and heating oil near 73. Electric heat depends on the grid; resistance heat mirrors grid emissions, while heat pumps multiply the usefulness of each kilowatt-hour, typically cutting emissions substantially where the grid is moderately clean or improving. As grids add more renewable generation, heat pump emissions tend to decrease over time without any equipment changes in the home.

Costs: Upfront, Operating, Maintenance, and Lifespan

Total cost of ownership blends the check you write on day one with the payments you make every month for energy and upkeep. Installed costs vary by region, home condition, and system size, but general ranges can guide planning. Many ducted furnaces fall roughly in the several-thousand-dollar range installed, hydronic boilers often higher due to piping complexity, and air-source heat pumps typically span modest to mid five figures depending on ducted or ductless configurations and the number of indoor zones. Ground-source heat pumps command a larger initial investment for drilling or trenching but can provide notable savings over time in the right conditions.

Operating costs hinge on both energy prices and efficiency. To make comparisons concrete, consider cost per MMBtu of delivered heat under illustrative assumptions:

– Electricity at $0.15/kWh: electric resistance roughly $44/MMBtu; a heat pump with COP 3 around $15/MMBtu

– Natural gas at $1.20/therm and 95% AFUE: roughly $13/MMBtu delivered

– Propane at $2.50/gal and 95% AFUE: around $29/MMBtu delivered

– Heating oil at $4.00/gal and 85% AFUE: around $34/MMBtu delivered

These figures are estimates; your actual costs will vary with local prices, weather, and system design, but the pattern usually holds: heat pumps and high-efficiency gas systems tend to deliver lower costs than electric resistance or oil in many markets.

Maintenance and lifespan also influence the ledger. Typical lifespans are often in these ranges: many furnaces 15–20 years, boilers 20–30, air-source heat pumps 12–18, ground-source heat pumps 20–25 (with ground loops commonly longer), and electric baseboards two decades or more with minimal moving parts. Annual checkups help catch small issues before they become expensive problems: cleaning burners or heat exchangers, checking condensate drains, verifying refrigerant charge and airflow on heat pumps, bleeding air from hydronic circuits, and confirming safety controls. Modest annual maintenance costs can pay for themselves through reliability and efficiency.

Upgrades that trim operating costs are often inexpensive compared with equipment replacement. Air sealing and insulation can reduce heating loads by double-digit percentages, letting you choose a smaller, less costly system while improving comfort. Zoning—whether via multiple ductless heads, hydronic circuits, or motorized dampers—can reduce waste in unused rooms. Smart controls that learn schedules or use occupancy and weather data can curb runtime without sacrificing comfort. When evaluating quotes, ask for a load calculation, a duct or hydronic assessment, and a breakdown of long-term operating costs—not just the sticker price.

Sizing, Distribution, and the Home Envelope

Even an efficient heater will underperform if it is the wrong size or paired with a leaky distribution system. Right-sizing starts with a formal heat loss calculation that accounts for your climate, insulation levels, air leakage, windows, and orientation. Oversized equipment short-cycles, creating uneven temperatures and noise; undersized equipment struggles on the coldest days. A careful design targets the building’s design load with reasonable headroom while prioritizing low-temperature operation (for hydronics) or variable-speed modulation (for air and heat pumps) to match real demand.

Distribution choices set the stage for comfort. Ducted systems benefit from sealed, insulated ductwork kept within conditioned space where possible. Return air pathways should be clear and appropriately sized so the blower does not fight against pressure imbalances. Hydronic systems need balanced loops and emitters matched to water temperature; upgrading to larger radiators or installing radiant floors can allow lower water temperatures and better seasonal efficiency. Ductless systems should be sited to avoid dead zones and deliver airflow along the length of key spaces.

The home envelope is the quiet hero of any heating plan. Air sealing cuts drafts, improves indoor air quality, and reduces peak loads. Insulation upgrades—attic first in many homes, then walls and rim joists—often deliver immediate comfort improvements. High-performance windows help, but sealing and insulating around existing frames can address many problems at a fraction of the cost. Simple steps often yield strong returns:

– Seal attic penetrations and top plates before adding insulation

– Insulate and air-seal rim joists and basement headers

– Weatherstrip doors and caulk window trim to reduce infiltration

These improvements reshape the system you need. A tighter, better-insulated home enables lower supply temperatures, quieter operation, and smaller equipment. Heat pumps benefit especially, maintaining high efficiency at lower loads and reducing the need for backup heat. Radiant floors can run cooler for the same comfort level, and furnaces can idle instead of cycling aggressively. When you invest first in the envelope, you buy comfort the system never has to produce.

Controls, Upgrades, Incentives, and a Decision Guide (Conclusion)

Controls bridge the gap between equipment capability and your day-to-day routine. Programmable and learning thermostats trim runtime when you are asleep or away. Weather-compensating boiler controls lower water temperature on milder days, boosting efficiency. Zoning lets different parts of the house call for heat independently—useful for multi-story homes or where sun exposure varies. On heat pumps, smart defrost strategies and lockouts for costly resistance backup can protect efficiency. Data logging and simple alerts help catch issues early, like a clogged filter or a stuck zone valve.

Public incentives and financing can help align upfront costs with long-term savings. Many regions offer rebates or tax credits for high-efficiency furnaces, boilers, air-source and ground-source heat pumps, and weatherization. Low-interest loans or on-bill financing can spread costs over time. Utility marketplaces often bundle rebates with installer networks, while energy audits may be subsidized, providing prioritized recommendations so you can tackle the envelope and equipment in sensible steps.

Here is a practical decision path you can adapt to your home:

– Start with an energy audit to identify air sealing, insulation, and duct/hydronic improvements

– Define your comfort goals: quiet operation, air filtration, zoning, or rapid warm-up

– Map local energy prices and likely trends; consider resilience needs during outages

– Request load calculations and detailed proposals for at least two system approaches

– Compare lifecycle costs: installed cost, operating cost, maintenance, and expected lifespan

– Plan for controls, filtration, and ventilation to meet indoor air quality goals

– Line up maintenance and set reminders for filter changes and annual service

Conclusion: Your home’s ideal heating solution is the one that fits your climate, your building, and your priorities—comfort, cost, and impact. If you live where winters bite hard, a high-efficiency furnace or a cold-climate heat pump with a modest backup strategy can deliver steady warmth. If you value whisper-quiet comfort, hydronic systems and radiant floors pair beautifully with efficient boilers or heat pumps. And if you plan to stay put, envelope upgrades plus right-sized equipment can make your home feel warmer at lower settings. Approach the choice methodically, and you will assemble a heating system that works as hard—and as quietly—as you need it to, year after year.